Introduction

One of our SAP Barcode customers is an automobile manufacturer. They were looking for ways to simplify the process for managing their vehicle inventory and part assignments to vehicles, in SAP. As each vehicle moves through their production line, many employees collectively need to post hundreds of inventory transactions throughout the day. Each vehicle will have many different parts installed, and the installation of these parts requires moving the vehicle to different locations within the production facility, and moving parts across plants. Each of these actions requires a transaction posting in SAP in order to track its current status and final state. Also, if certain transactions are not committed in a timely manner, subsequent transactions to SAP cannot be posted even though the jobs themselves have been completed.

The challenge not only involves posting the transactions to SAP in real-time, but also to simplify the process of posting these transactions for the employees. Much of the posting data are static values unique to the employee assigned to the particular area of the plant. And some of the postings require data that are unknown to the employee committing the posting transaction. As a result, employees need to spend additional and unnecessary time keying in repeated data, or searching for the unknown data in order to satisfy the minimum input requirements for a successful posting to SAP. All of these issues combined to make the processing of vehicles through the plant inefficient.

The Solution

By designing the barcode to include most of the static data that employees need to input, and by using a barcode system to automatically look-up or store the unknown values to satisfy the posting requirements, this customer significantly simplified the potentially time-consuming task of transaction posting for the employee down to simple steps of “Scan” and “Post”; with the occasional need for quantity input.

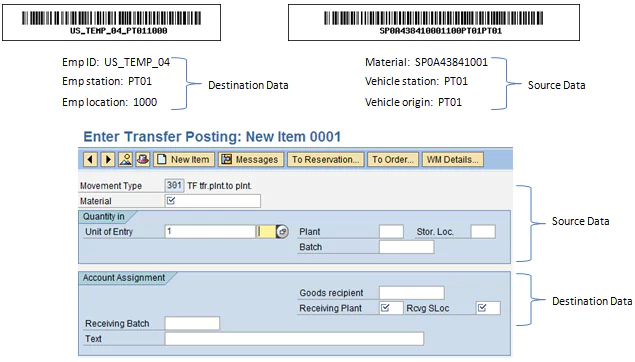

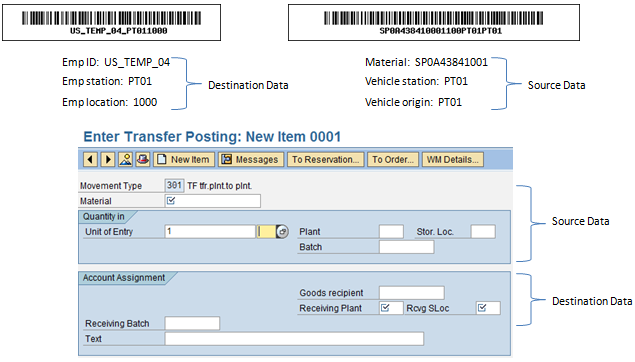

Each employee is provided with an employee badge with a single barcode that includes all the static values unique to the employee, (such as plant, location, etc.). Each vehicle and vehicle part is assigned a single barcode with data to satisfy any unknown values, (for example, material number, cost center, etc.).

As each vehicle moves into the work cell where the employee is assigned, the employee simply scans the barcode on their ID badge followed by the barcode on the vehicle, to complete the movement transaction in SAP. When the employee installs a part on the vehicle, the employee simply scans the barcode on the vehicle, followed by the barcode on the part, to complete the issue transaction in SAP.

Benefits

By dramatically simplifying the SAP transaction posting process, employees are much more willing to use the new SAP barcoding system, and SAP is now able to track and report the accurate status of all the vehicles in real-time; making the overall process significantly more efficient and effective.

Ideally, SAP barcoding systems should be designed so that the users can simply “Scan and Go”. In order to support a “Scan and Go” methodology it can sometimes be beneficial to be creative with barcode design, (such as stringing multiple sets of data together into one single barcode), and the underlying SAP barcoding system must be able to easily look-up any required data, from one or more systems, before posting it to SAP in real-time.

The NLINK® ADC to SAP Solution fully supports a “Scan and Go” methodology through its ability to perform real-time SAP data lookups; for validation, to provide contextual data for the users, and to collect the additional data required to successfully post to SAP. NLINK SAP Barcoding provides a powerful and flexible SAP barcoding centric business rules engine via a zero-code approach that does not install anything into your SAP landscape.